RAFT 聚合技術(shù)首先由Rizzardo 等于1998年在第37 屆國(guó)際高分子大會(huì)上公布。該過(guò)程是一個(gè)可逆反應(yīng), 稱為可逆加成-裂解鏈轉(zhuǎn)移過(guò)程(Reversible Addition-Fragmentation chain Transfer)��,即 RAFT�����。RAFT體系適用的單體種類多,聚合所需溫度較低���,可制備較高分子量的窄分布聚合物�����,因此具有廣闊的應(yīng)用前景�����。

百靈威攜手國(guó)際知名品牌STREM�,一同推出應(yīng)用廣泛的RAFT試劑��,以滿足客戶的實(shí)驗(yàn)需求��。

.jpg)

RAFT technology

CSIRO and DuPont have developed an innovative technology known as RAFT (for Reversible Addition Fragmentation chain Transfer), which allows for the synthesis of specially designed polymeric materials with enhanced properties. CSIRO has licensed this technology to Strem to make available to you for research purposes.

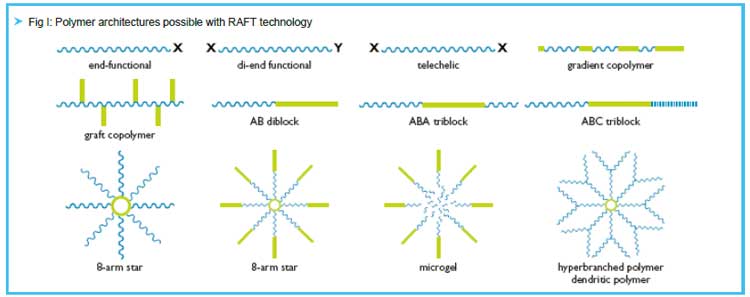

RAFT technology is a sophisticated form of controlled free radical polymerization. Often known as 'living polymerization' (it can be stopped and restarted at anytime) this technology enables the synthesis of tailored polymers with unprecedented control over composition and architecture.

Polymers may be synthesized more readily, using RAFT technology,

• With predetermined molecular weight and narrow molecular weight distributions over a wide range of monomers and reaction

conditions,

• With reactive terminal groups that can be purposely manipulated, including further polymerization,

• With complex architecture, including A B diblock, A B A triblock, graft, star; gradient and branched polymers (see Fig I),

• That are based on scaleable manufacturing processes utilizing conventional processing equipment.

RAFT technology can be used with a wide range of monomers and monomer mixtures, and can be used in all modes of free radical polymerization, including solution, emulsion and suspension polymerizations. This allows for an unlimited array of tailored compositions and complex architectures under standard conditions.

The RAFT process

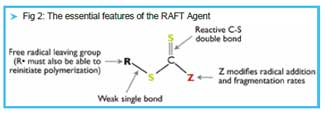

Implementing the RAFT process can be as simple as introducing a suitable chain transfer agent, known as a RAFT Agent (see Fig 2), into conventional free radical polymerization, while employing plant and equipment. The RAFT Agents allow for the preparation of polymers with low polydispersity, well-defined microstructure and predetermined molecular weight.

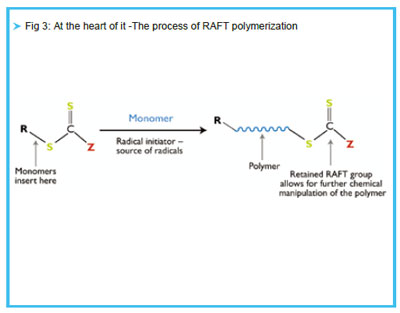

As the newly formed polymer is terminated by an active RAFT group, thereby rendering it a RAFT Agent in its own right, it is capolymerization reactions or can be subjected to other chemical manipulations (see Fig 3). Incorporation of the RAFT Agent in the need for its removal, thereby simplifying the isolation and friendly process that does not require expensive and contaminat Further detailed information on RAFT technology may be found in the following references:

• Living Free-Radical Polymerization by Reversible Addition-Fragmentation Chain Transfer:The RAFT Process.J. Chiefari, et al, Macromolecules, 1998,31,5559-5562.

• Living Radical Polymerization by the RAFT Process. G. Moad, E. Rizzardo, S. H.Thang, Aust. J. Chem. 2005,58, 379-410.

• Living Radical Polymerization by the RAFT Process -A First Update.G. Moad, E. Rizzardo, S. H.Thang, Aust. J. Chem. 2006,59, 669-692.

*Content reproduced with permission of CSIRO.

The RAFT process is typically started by a separate,commercially available, free radical initiator. The RAFT Agent is rapidly incorporated into the growing polymer and facilitates further growth of the polymer by incorporating monomer, one unit at a time. Incorporation of the RAFT Agent into the final polymer results in a cleaner and more versatile product.

Overall, RAFT polymerization results in:

•Polymers with contro lled molecular weight

•Narrow distribution of molecular weight, i.e. low polydispersity

•The ability to incorporate, in a defined sequence, one or more type of monomers in the polymer chain

•The RAFT group being retained in the final polymer, and

•The opportunity for further chemical manipulation of the RAFT group, including further polymerization or removal